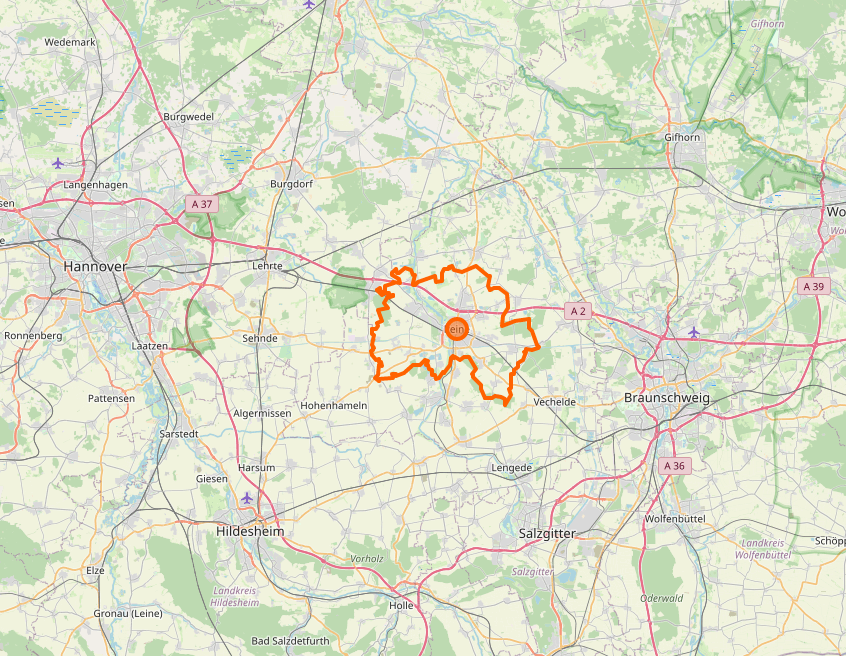

Location

The Peine production location is the administrative centre of the Peine rural district right off the A2 motorway between Braunschweig and Hanover. The town of Peine was founded in the 13th century around the former Peine Castle and is now the centre of Peine rural district, which has around 50,000 inhabitants.

The medieval town centre with its lovingly restored half-timbered architecture is surrounded by modern residential areas. Peine offers a wide range of cultural and social events. The state capital, Hanover, and the city of Braunschweig, with their many different cultural offerings are less than 30 minutes away.

The largest production company in the town is the Salzgitter AG steelworks. Peine is also home to many SMEs, such as PEINER Umformtechnik.

Quality

Environmental Protection – Occupational Safety

PEINER Umformtechnik uses innovative and modern production machinery and has in place the latest organisational structures. The quality assurance system is certified to DIN ISO 9001 and IATF 16949. Its environmental management is certified to ISO 14001.

To maintain the highest possible level of safety at work, PEINER Umformtechnik has implemented an occupational safety management system which is certified to OHSAS 18001. If you are interested, the quality policy can be viewed in the company.

Please make an appointment with our quality manager Mr. Torsten Held (phone: +49 5171 / 545-202 or e-mail: t.held[at]peiner-ut.com).

Processes

For metal forming, PEINER Umformtechnik uses two different production methods

Cold forging is done on state-of-the-art multi-stage presses. Hot forging uses multi-stage presses for nuts and other components with a similar geometry and single-stage presses for screws, bolts and threaded sections on shafts. Technical and economical factors influence the choice of the right production method for our customers’ individual needs. Threads and other profiled components are produced on modern rolling mills.

Computer-controlled machining centres are used for process steps which require cutting or grinding. Hardening of the products takes place in process-stable equipment which uses the latest heat treatment technologies. Surface coating to protect against corrosion is carried out for PEINER Umformtechnik by approved and monitored service companies who are specialised in this field.

Engineering

Technical application advice

Our key-account managers advise our customers on all aspects of mechanical fasteners, for example the choice of the appropriate fastening system, design of the fastening system, dimensioning and assembly. We keep ahead of the latest technical developments on all levels. We take part in research programmes at higher education institutes and universities, and we play an active, leading role in regulatory bodies and national (DIN) and international (CEN, ISO) standardization commissions. In addition, we carry out training seminars to inform our customers about recent changes to product standards, design and assembly regulations.

Optimised processes

All of PEINER Umformtechnik’s manufacturing processes are continuously reviewed and cost optimised. Modern management methods create a continuous process of improvement, which, in turn, leads to continuous further development of the manufacturing processes.

Customer-specific product development

A lot of experience is required to design high strength fasteners. Our development engineers plan and implement the best solutions in terms of functionality, manufacturing and cost efficiency in close cooperation with our customers’ development and design departments. Together with our own tool production specialists, our design department routinely takes on challenging tasks, including the modification and further development of existing mass produced components. The development work considers all aspects of the design and the manufacturing process with the aim of optimising the overall costs of the fastener.